Research

THE FACULTY OF CHEMICAL AND PROCESS ENGINEERING RESEARCH ACTIVITY

Scientific research conducted at the Faculty is in line with the new development directions of the chemical engineering scientific discipline, allowing the use of its research potential, especially in the areas of:

- industrial processes intensification (highly effective and economical equipment and process solutions, also in biotechnology)

- methods of obtaining functional materials with predefined properties and their applications:

- for sustainable development (m.in low-carbon technologies, new energy sources, bio-based processes, and environmental protection),

- in nanotechnology,

- in medical technologies.

Students and doctoral students actively participate in research conducted by the Faculty, fulfilling the mission of Warsaw University of Technology as a research university. The areas of scientific activity are constantly expanding thanks to cooperation with industry and partnerships with Polish and foreign research centres. In recognition of its outstanding activity, the Faculty received the prestigious Certificate of Excellence in Education in the category "Partner for development - excellence in cooperation with the socio-economic environment" awarded by the Polish Accreditation Committee in 2022.

Below we briefly present the most important areas of the Faculty's scientific activity.

1. Industrial process intensification, chemical reactors, and bioreactors

Our ability to combine knowledge in physics, chemistry, and biology enables pioneering research on the border of traditional scientific disciplines. Integrating experimental and computational approaches leads to the effective development of new process solutions that increase efficiency and reduce production costs. This approach is also used in interdisciplinary research, expanding the area of interest often attributed to chemical engineering.

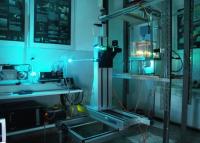

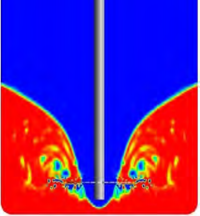

The work of the Product Engineering Team focuses both on experimental research - conducted either on a lab scale or on the premises of industrial partners- and on the theoretical interpretation of the studied phenomena and computer modelling of the course of processes at various scales. For example, computational fluid mechanics is used in studies on the production of particles and suspensions, considering the population balance. The team's work scope includes designing, scaling up, and conditions adjustment for conducting processes in industrial installations using programs for computer-aided chemical engineering.

The Research Team of Chemical Reactor Engineering has extensive experience in experimental research, mathematical modelling, design, and optimisation of chemical reactors and bioreactors, gained during the implementation of numerous research and R&D projects in cooperation with scientific and industrial partners.

One of the innovative areas of the Faculty's activity is the utilisation of supercritical fluids. The SCF-LAB deals with physical and reactive supercritical extraction, including the raw materials of natural origin and the production and processing of functional materials. Laboratory employees have extensive experience in designing, experimental research, and mathematical modelling of high-pressure processes.

Research work in the flow reactors operation modelling fieldfor mixing liquids in a wide range of shear rates enabled the development of the process for producing emulsions with different structures. The Team's interests include the preparation of concentrated emulsions, therapeutic encapsulation techniques, studies, and modelling of the drug release and transport process.

The Research Team of Thermochemical Hydrogen Production and Pyrolysis Processes develops an innovative method of hydrogen production due to the direct conversion of biogas to hydrogen and coal in a microwave catalytic reactor. The team also has extensive experience obtaining hydrogen and syngas through classical methods (steam and dry reforming) and innovative methods, e.g., obtaining hydrogen with simultaneous CO2 sequestration. The team also researched the pyrolysis of rubber, electronic, and packaging waste and refining pyrolysis products.

The Nanodispersions of Gases in Liquids Team researches the nature and stability of gas nanodispersions and their application in bioprocess engineering and medicine. Nanodispersions are used, e.g., in the food industry (beverages with oxygen or hydrogen nanobubbles), for wastewater treatment (flotation, COD reduction), in agriculture (enhancing the growth of plants and animals) and in medicine (supporting circulation, treating chronic wounds), as well as in industrial biotechnology (intensification of biomass growth, intensification of mass transfer in cultures).

Bioreactors are the area of interest of the SU-BIOreactor Team. The researchers have experience in modelling the conditions of mixing and mass transfer in single-use bioreactors and their application for the cultivation of animal cells, plant cells and organs, and microorganisms. The team also works on the liquid perfluorinated respiratory gas carriers and biomaterial matrices for the intensification of bioprocesses.

Research in the field of lignocellulosic biomass processing focuses on the search for the most favourable conditions for conducting the main stages of this process (pre-treatment, enzymatic hydrolysis, fermentation, purification) into valuable products, including biofuels, using enzymes.

2. Manufacture of (nano)functional materials and their targeted applications in technology and medicine

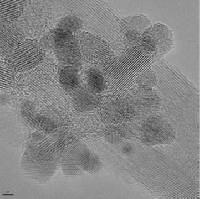

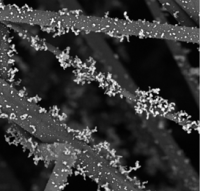

The research activity of the Graphene Laboratory focuses on the production and characterisation of carbon nanomaterials (such as graphene oxide GO, reduced graphene oxide rGO, multi- and single-walled carbon nanotubes SWCNTs and MWCNTs, nanoparticles and carbon dots CNPs and CNDs) and other functional products in the form of nanoparticles. These materials are used as catalysts in formic acid electrooxidation, oxygen reduction, hydrogen evolution, and photocatalysis reactions. In addition, the activity of the Laboratory includes the production of polymer composites with thermal insulation properties, high mechanical strength, and conductive properties (membranes, foams), as well as lubricants based on molybdenum disulphide and nanocarbon composites.

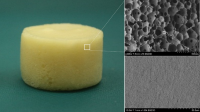

Novel materials, including for regenerative medicine, are being developed in the Biomedical Engineering Laboratory (BioMedLab). Scientists investigate the production and characterisation of nanostructures, microgranules production for cartilage defects and bone-filling, functional polymer and ceramic nanoparticles, increasing the biocompatibility and hemocompatibility of medical device coatings and other functional surfaces. The research team produces various tissue scaffolds to regenerate blood vessels (vascular prostheses), bones, cartilage, muscles, and nerves.

One of the developed technologies concerns the synthesis of modified hydroxyapatite nanoparticles. The members of the Team deal with both the selection for the nanoparticle production conditions, allowing for obtaining particles of the desired size and morphology and their functionalisation. Such particles can be used as drug carriers, obtained directly during their manufacturing processes or as a result of post-processing. Team’s research includes the development of a reactor for the continuous synthesis of material, as well as the formation of composites from nanohydroxyapatite and polymers for 3D printing.

The Team of Aerogel Engineering deals with the porous material synthesis targeted for various applications, e.g., for modifying air and water filters, obtaining biological substrates, or supporting matrices for solar distillation systems. The activity of the Team focuses on both practical (synthesis of a product with desired properties using the sol-gel technique) and theoretical aspects (mathematical modelling of the process).

3. Distributed systems in environmental protection and medicine

Production processes are inevitably associated with the generation of waste streams, the management of which is a vital element in reducing the technology's impact on the natural environment and, indirectly, human health. Most often, these streams are created by dispersed systems, such as suspensions, emulsions, foams, and aerosols, all of which require targeted methods for their separation or purification.

In the Laboratory of Water, Liquid Fuels and Process Gases Filtration, investigate the utility of depth filters for water purification and coalescing filters for the W/O (fuel dewatering) and O/W (water deoiling) emulsions separation or oil and water mist removal from gas. The conducted research focuses on nonwoven filter optimisation in terms of structural parameters, as well as methods of their modification, giving the filters specific functional properties appropriately selected for real-life applications.

The employees of the Faculty also dispose of advanced research infrastructure in the field of various membrane separation techniques. The Membranes and Membrane Processes Team focuses on membrane production and functionalisation research and activities related to the membrane processes implementation in the industry. The most important current applications developed with the team relate to the membrane removal of surfactants and pharmaceuticals from wastewater.

The Aerosol Filtration Team (AEROFIL) represents a comprehensive approach to the gas filtration issue, including the design and manufacture of non-woven filtration structures using the melt-blown technique, modification of existing filtration mats by functionalization of the fibre surface, testing the effectiveness of the obtained structures in various process conditions and mathematical modelling of the filtration process aerosol particles in polymer non-woven filters.

Research on dispersed systems in the gas phase is also conducted at the Aerosol Mechanics Laboratory (AEROLAB). They aim to analyse the impact of aerosol particles' shape, size, composition, and source on their behaviour in the external environment and the possibility of penetrating and interacting with the human body. The mathematical modeling and measurements carried out in vitro to reflect the physiological conditions are used for the analyses. The discussed issues concern toxicological and therapeutic aspects regarding the working environment safety and health protection.

Another research activity example in the area of distributed systems is research on the aerosol properties in the context of their applications in medicine (drug inhalation), cosmetics, and household chemistry products. The Respi-Lab Team investigates the characteristics of aerosol systems, inhaled particle deposition assessment in individual parts of the respiratory system, and their impact on the lung surface as a result of direct physicochemical interactions, for example, with pulmonary surfactant. In addition to the purely scientific aspect, the work has a practical value, allowing for the quantitative characterization of the operation of the inhaler and the development of new types of such devices, as well as the development and/or quality comparison of medicinal products for inhalation.