Faculty of Chemical and Process Engineering » Research » Research teams » Laboratory of Nanohydroxyapatite (LabOFn) »

Project: Innovative polymer composites for filling bone defects – INPOLYBOND

Project objective

In response to the market demand for medical products, the project will develop and market new polymer biocomposites containing innovative patented nanohydroxyapatite (nHAp). Based on the principle of biomimetics of the natural bone structure, a product will be created that optimally combines organic and mineral phases. Its distinguishing features will be:

- Similarity to native apatite through the use of surface-modified nHAp.

- Improved cohesion for cement (drillability).

- The presence of polymers provides the desired final form of the product (plasticity) and a suitable microenvironment for cells.

- Macropore formation in vitro.

- Bioresorbability of filling bone defects.

All these features will allow us to meet the requirements that are set for materials used in regenerative medicine.

Planned outcomes of the project

The project will result in the creation of injectable bone substitute materials based on nanostructured hydroxyapatite, with physicochemical properties modified with polymers. Among the products planned to be obtained, we can distinguish two main lines: (1) a product for restoring bone micro-cavities and (2) bone cement.

The product's convenient application form and improved mechanical properties, as well as its cohesion, are properties that are highly sought after by clinicians. The launch of innovative products with the characteristics mentioned above will increase the range of bone regeneration materials available in Poland to date. The new products will be characterised by solutions that have been absent from the competition so far.

The objective of the step carried out at the Warsaw University of Technology

To develop and optimise the process of obtaining lecithin-modified nHAp (nHAp-PC), which will be the essential component of the biomaterials created in the project.

Planned results of the step carried out at the Warsaw University of Technology

Optimised process of obtaining nHAp-PC in the form of nanoparticles forming aggregates, produced under different conditions of the proposed synthesis. Formulation of criteria for selecting the final material for use in Biovico-created restorative materials and cements. The prepared process will allow the creation of a biocomposite as a material for bone tissue regeneration in the following stages of the project.

Implementation of the stage at the Warsaw University of Technology

The task of the team led by Professor Tomasz Ciach was to develop and optimise a continuous production method for lecithin-modified hydroxyapatite nanoparticles (nHAp-PC) in an efficient and reproducible manner. The process developed was based on the technology for obtaining nanoparticles patented by the BioMedLab team. The implementation of the step was divided into three tasks, including 1) development of the process for obtaining nHAp, 2) characterisation of the powders obtained, and 3) optimisation of the process. The work in the INPOLYBOND project aimed to prepare a process to obtain nanoparticles forming aggregates, which, due to their physical and chemical properties, would be beneficial for applications in composite materials used to fill bone defects.

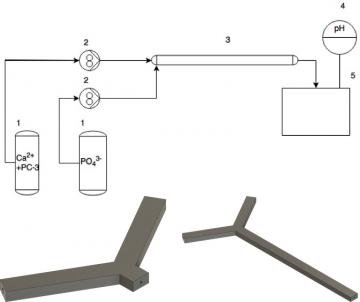

A continuous process for preparing nHAp-PCs using collision mixers (reactors) with a collision angle of 120° fluxes (Y-type) was proposed. Different mixing times of the reactants, i.e. different lengths of the mixers, were analysed. A schematic diagram of the apparatus and a graphical representation of the mixers are presented in Fig. 1.

Fig. 1. Schematic of the test installation: 1) reagent tanks; 2) dosing pumps; 3) mixer (reactor); 4) pH meter; 5) product tank. Below are 3D models of the impact mixers (reactors) used with Y-type geometries.

The particles obtained were analysed by the following techniques: electron microscopy SEM (nanoparticle size), nanoparticle tracking NTA and dynamic laser light scattering DLS (aggregate size), electrophoretic mobility (zeta potential, aggregation tendency), FTIR-ATR spectroscopy (presence of chemical functional groups) and X-ray crystallography XRD (crystal structure and phase purity).

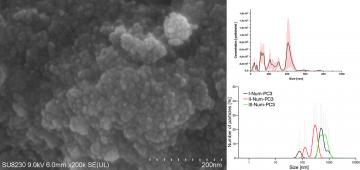

Fig. 2. Scanning electron microscopy (SEM) image showing spherical nanoparticles obtained in Y-type mixers (reactors) (left). Numerical size distributions of nanoparticle aggregates measured using different techniques (right).

The goal of obtaining particles with sizes on the nanometre scale (10-30 nm) forming larger aggregates (even up to 800 nm) was achieved - Fig. 2. The chemical and crystallographic properties corresponded to hydroxyapatite presented in the literature. Lecithin was present in the structure of the particles obtained (FTIR-ATR result published in the papers mentioned below).

The most important results obtained are presented above, excluding those that will form the basis of a patent application in preparation (reactor with increased efficiency for obtaining aggregates of nHAp-PC nanoparticles) or scientific publications in preparation (detailed results of analysis of the influence of selected process parameters - optimisation - on the properties of continuously obtained nHAp-PC powders).

In addition, our team worked on a technique to determine the amount of lecithin in nHAp-PC powders. The results will be made public once the publication manuscript has been developed and prepared.

Team

- prof. dr hab. inż. Tomasz Ciach - PI

- mgr inż. Joanna Latocha

- dr inż. Michał Wojasiński

- Students:

- Paulina Liszewska

- Klaudia Jurczak

Project results presentations - conferences

- 4th World Congress and Expo on Nanotechnology and Materials Science, international conference, Barcelona 2017, a poster entitled: Hydroxyapatite nanoparticles properties in lecithin-based wet chemical precipitation, authors: M.Wojasiński, J.Latocha, P.Sobieszuk, T.Ciach;

- X Jubileuszowa Konferencja Naukowa INŻYNIERIA PROCESOWA W OCHRONIE ŚRODOWISKA połączona z mikrosympozjum „Bioinżynieria 2017”, Polish conference, Sarbinowo 2017, presentation and paper entitled: Wpływ temperatury na właściwości nanocząstek hydroksyapatytu otrzymywanych w precypitacji z lecytyną (in Polish), authors: M.Wojasiński, J.Latocha, P.Sobieszuk, T.Ciach (published in Inż. Ap. Chem. 2017, 56, 4, 148-149)

- 7th European Young Engineers Conference, international conference, Warsaw 2018 (23-25 April), a poster entitled: Synthesis of hydroxyapatite nanoparticles in continuous reactor: preliminary experimental results, authors: J.Latocha, M.Wojasiński, P.Sobieszuk, T.Ciach

- NanoTech Poland 2018 & Symposium on Polydopamine, international conference, Poznań 2018 (6-9 June), a poster entitled: Solution Blow Spun Poly-L-Lactic Acid/Ceramic Fibrous Composites, authors: M.Wojasiński, J.Latocha, P.Sobieszuk, T.Ciach (prized)

- II Doktoranckie Sympozjum Nanotechnologii NanoMat, Polish conference, Łódź 2018 (21-22 June), a presentation entitled: Synteza nanocząstek hydroksyapatytu w reaktorze przepływowym (in Polish), authors: J.Latocha, M.Wojasiński, K.Jurczak, S.Gierlotka, P.Sobieszuk, T. Ciach (prized)

- 4th International Conference on Biomedical Polymers & Polymeric Biomaterials , international conference, Kraków 2018 (15-18 July), a poster entitled: Solution Blow Spun Poly-L-Lactic Acid/Ceramic Fibrous Composites, autorzy: M.Wojasiński, J.Latocha, P.Sobieszuk, T.Ciach

- XII Ogólnopolska Konferencja Przepływów Wielofazowych, XIV Ogólnopolskie Seminarium "Mieszanie", Polish conference, Olsztyn 2018 (3-5 October), presentation and paper entitled: Zastosowanie metody ChZT do oznaczania stężenia lecytyny w syntetycznym hydroksyapatycie (in Polish), authors: J.Latocha, M.Wojasiński, R.Jeżak, K.Matusiak, T.Ciach, P.Sobieszuk (Inż. Ap. Chem. 2018)

- 12th European Congress of Chemical Engineering, international conference, Florence 2019 (15-19 September), a poster entitled: Continuous synthesis and characterization of hydroxyapatite nanoparticles modified with lecithin, authors: J.Latocha, M.Wojasiński, P.Sobieszuk

Publications of the project results

- M.Wojasiński, J.Latocha, P.Sobieszuk, T.Ciach. Wpływ temperatury na właściwości nanocząstek hydroksyapatytu otrzymywanych w precypitacji z lecytyną (in Polish). Inż. Ap. Chem. 2017, 56, 4, 148-149

- J.Latocha, M.Wojasiński, R.Jeżak, K.Matusiak, T.Ciach, P.Sobieszuk. Zastosowanie metody ChZT do oznaczania stężenia lecytyny w syntetycznym hydroksyapatycie (in Polish). Inż. Ap. Chem. 2018, 57, 3, 67-68

- J.Latocha, M.Wojasiński, P.Sobieszuk, T.Ciach. Synthesis of hydroxyapatite in a continuous reactor: a review. Chem. Process Eng., 2018, 39 (3), 281–293

- J.Latocha, M.Wojasiński, K.Jurczak, S.Gierlotka, P.Sobieszuk, T.Ciach. Precipitation of hydroxyapatite nanoparticles in 3D-printed reactors. Chem. Eng. Process. 2018, 133, 221-233

- J.Latocha, M.Wojasinski, S.Gierlotka, P.Sobieszuk, T.Ciach. Impact of morphology-influencing factors in lecithin-based hydroxyapatite precipitation. Ceram. Int. 2019, 45 (17-Part A), 21220-21227

- M. Wojasiński, J.Latocha, P.Liszewska, Ł.Makowski, P.Sobieszuk, T.Ciach. Scaled-Up 3D-Printed Reactor for Precipitation of Lecithin-Modified Hydroxyapatite Nanoparticles. Ind. Eng. Chem. Res. 2021, 60 (35) 12944–12955

- Polish Patent PL244036-B1: Reaktor do ciągłej syntezy nanocząstek hydroksyapatytu (in Polish). J. Latocha, M. Wojasiński, P. Sobieszuk, T. Ciach, Ł. Makowski, P. Liszewska.

Funding

Project title: "Innovative polymer composites for filling bone defects"

Project data: 4.1 Scientific research and development of the Operational Programme Intelligent Development 2014-2020 co-financed by the European Regional Development Fund

Contract number: POIR.04.01.04-00-0133/15

Project timeline: 01.01.2016 to 31.12.2020 (5 years)

Timeline for step 2 carried out at the Warsaw University of Technology: 1.01.2016 to 31.12.2017 (2 years)

Funding (total): 6 274 385,00 PLN; EU co-funding of 4 566 444,00 PLN

EU co-funding for step 2 carried out at the Warsaw University of Technolgy (100%): 379 080,00 PLN

Project consortium: Biovico, sp. z o.o. (Lider) and Warsaw University of Technolgy, Faculty of Chemical and Process Engineering

|

|

|

|