Product Engineering Team

The Team operates within the Department of Industrial Process Intensification

Areas of activity: chemical engineering, materials engineering

#product engineering, #mixing processes, #separation processes, #chemical reactor engineering, #multiphase systems, #crystallization, #precipitation, #nanoparticles, #powders, #suspensions

Team Leader

| Name | Room | Phone | |

|---|---|---|---|

| Makowski Łukasz, prof. dr hab. inż. | 219 | +48 22 234 62 94 | Lukasz.Makowski.ichip@pw.edu.pl |

Members

| Name | Room | Phone | |

|---|---|---|---|

| Bojarska Zuzanna, dr inż. | 218 | +48 22 234 63 15 | Zuzanna.Bojarska@pw.edu.pl |

| Gierycz Paweł, prof. dr hab. inż. | 217 | +48 22 234 64 47 | Pawel.Gierycz@pw.edu.pl |

| Krzosa Radosław, dr inż. | 233 | Radoslaw.Krzosa@pw.edu.pl | |

| Krzywda Roman, dr inż. | 234 | +48 22 234 62 74 | Roman.Krzywda@pw.edu.pl |

| Małolepszy Artur, dr | 215 | +48 22 234 63 50 | Artur.Malolepszy@pw.edu.pl |

| Mazurkiewicz-Pawlicka Marta, dr inż. | 214 | +48 22 234 62 48 | Marta.Pawlicka@pw.edu.pl |

| Orciuch Wojciech, dr inż. | 220 | +48 22 234 64 91 | Wojciech.Orciuch@pw.edu.pl |

| Wojtas Krzysztof, dr inż. | 235 | +48 22 234 62 75 | Krzysztof.Wojtas@pw.edu.pl |

Research and development activities

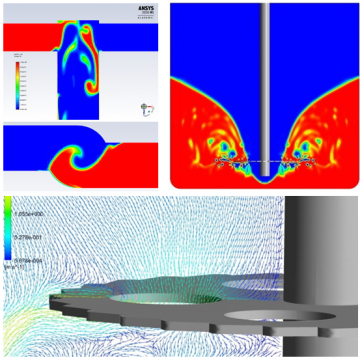

The team is engaged in solving practical problems in the field of manufacturing and processing micro- and nanoparticles with specified properties, selective manufacturing of products of complex chemical reactions, studying the rheology of suspensions in relation to their structure and separation processes. The team's work focuses on both experimental research conducted in our own laboratories or at industrial partners', as well as on theoretical interpretation of the studied phenomena and computer modeling of the course of processes at various scales based on computational fluid mechanics and population balance.

The team also performs work in the field of design, scaling up and selection of process conditions for conducting processes in industrial installations using programs for computer-aided process engineering.

The team offers research and expertise on processes in the chemical, pharmaceutical, food, cosmetics, waste processing, paint and varnish production and many others. It also offers measurements of particle size distribution, rheology of liquids and suspensions, tribological properties, velocity distribution and concentrations.

Key research equipment

-

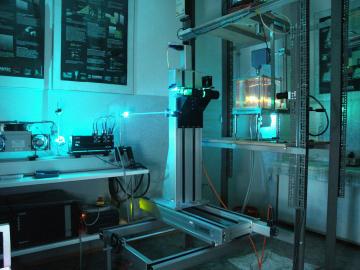

Particle Image Velocimetry (PIV) measuring system

- Planar Laser Induced Fluorescence (PLIF) measuring system

- Doppler Anemometry (LDA) measuring system

- Beckman Coluter LS 13 320 and Malvern Zetasizer micro- and nanoparticle size analyzers

- PERLAN Technologies Agilent 1260 Infinity HPLC liquid chromatograph

- Anton Paar MCR 302 rotational rheometer

- T-PTD200, T-PID/44 Anton Paar Tribometer

- Computational servers and software for computational fluid dynamics (CFD)

- Test stations for tank and collision mixers and reactors at various scales

- Ultrasonic and high-speed disintegrators

- Industrial-scale equipment: high-speed ball mill, tank dissolver

Services offer

- Design, modification and optimization of industrial processes and devices based on experimental research and computer modeling

- Selection of process parameters and construction of industrial devices in terms of efficiency, product properties, raw material and energy savings

- Studies of rheological and tribological properties of liquids and suspensions

- Studies of properties of dispersed systems, especially suspensions and emulsions

- Production and processing of nano- and microparticles with given properties

- Design of processes for selective production of products of complex chemical reactions

- Modeling of product manufacturing based on computational fluid mechanics and population balance

Example projects and cooperation

- Large-eddy simulations of complex chemical processes occurring in collision reactors, NCN, 2017

- Interpretation, modeling and CFD calculations of process involving comminution of particles, industrial project for Bayer Technology Service, 2017

- Development of utility models for the construction of a set of energy-saving devices for the chemical industry, in particular the production of paints and varnishes; industrial project for ICHEMAD-Profarb, 2018

- Study of the kinetics of molybdenum disulfide crystal formation in order to obtain a product with the desired properties in collision reactors, NCN, 2021

- Cooperation with industry: BASF, Bayer, Unilever, Cuf-Quimicos Industriais, DSM, Givaudan Suisse, Huntsman, Solvay, ICHEMAD-Profarb, Grupa Azoty, Anwil, hubergroup Polska